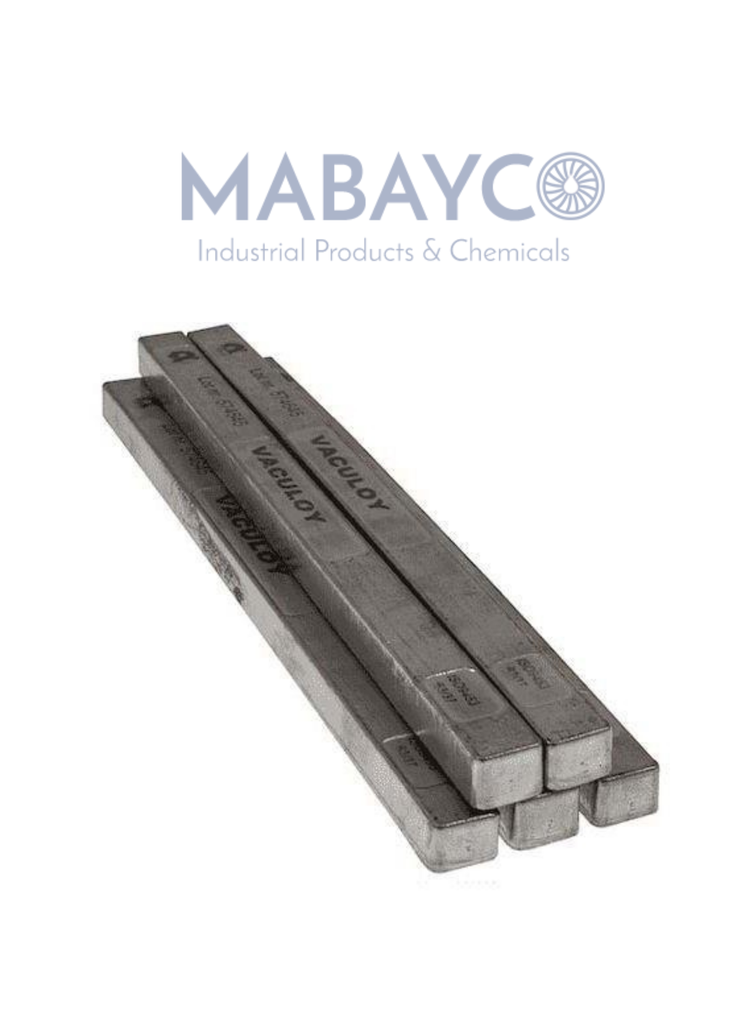

Vaculoy is manufactured using high purity raw materials and the alloy is conditioned using Alpha’s Vaculoy viscosity and dross lowering treatment. This results in a pure low dross high fluidity solder alloy, which is free of cast in impurities and included oxides.

Features:

VACULOY treated prior to casting: this removes finely divided suspended oxides that are found in all virgin raw materials. This increases the fluidity and hence soldering defects.

• The remove of the finely divided oxide reduces drossing rate, the wave stays cleaner, longer.

• Has a proven track record; no need to take chances.

Application:

VACULOY is the ideal companion product for all wave soldering systems. VACULOY is idea for the following types of applications:

• High volume wave soldering processes

• Applications requiring dual wave and chip wave systems

• Boards that are densely populated

A solder pot temperature of 240-250° is recommended. For suitable wave solder fluxes, please see our selector guide. Reclaim services, including dedicated lead-free containers, are also available. Please consult your local sales office.

Once the user has seen at least one product this snippet will be visible.